Technology

Connect world & Forge future

-

Gravity casting

Gravity castingGravity casting, as a pioneering process in the industrial production of automotive aluminum alloy wheels, can be traced back to the 1970s. This process, with its stable production characteristics, significantly improves the mechanical properties of the product (including tensile strength, elongation, and fatigue life), while achieving an optimized balance between production efficiency, cost control, and product performance. To this day, gravity casting remains the preferred mainstream production process in the global hub manufacturing industry.

Tyotaku, with mature gravity casting technology and strict quality control system, has the ability to quickly customize multi specification products, which can fully meet the differentiated needs of different customers such as sedans, SUVs, and commercial vehicles; Our excellent cost-effectiveness makes it easy for us to become the first choice for customers.

-

Low pressure casting

Low pressure castingLow pressure casting is an upgraded version of gravity casting, which achieves a 20%+increase in wheel strength and a 95% material utilization rate through precise pressure control, reducing waste and energy consumption. It is particularly suitable for lightweight needs such as new energy vehicles and high-end models.

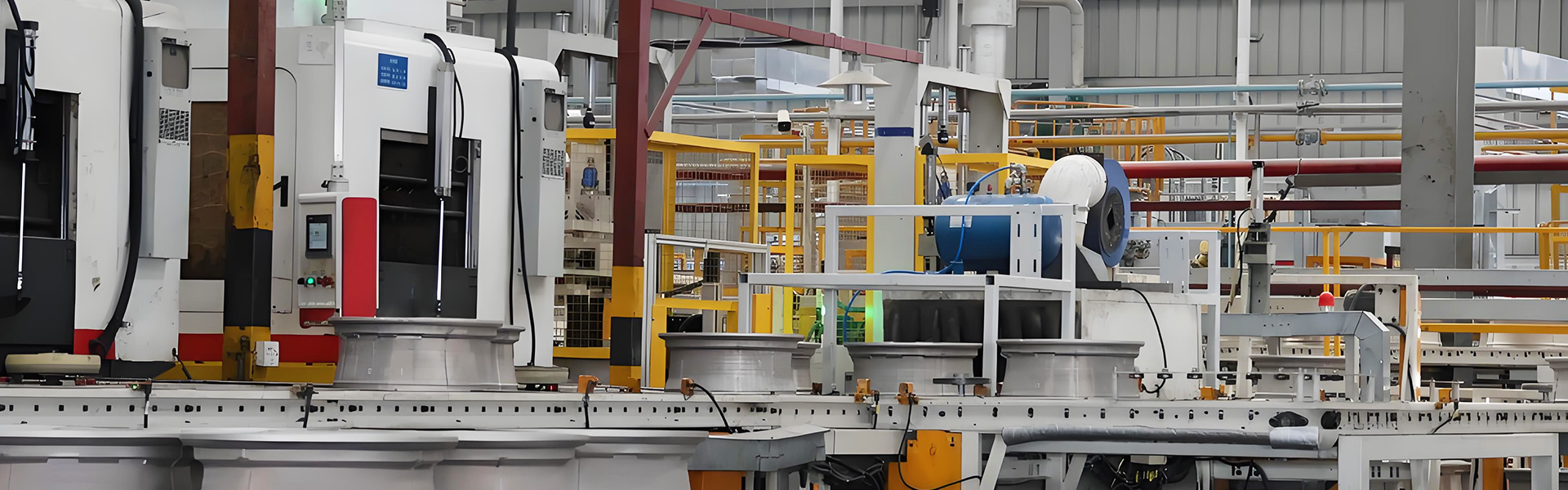

The Tyotaku low-pressure casting process adopts a fully automated production line, which achieves directional filling of aluminum liquid through precise pressure control (0.5-1.5 bar), effectively eliminating porosity and cold shut defects, and ensuring the density of castings. The intelligent system integrates real-time process monitoring and AI quality inspection. Each wheel hub undergoes X-ray non-destructive testing and dynamic balance testing to achieve 100% full inspection.

Tyotaku low-voltage products strictly comply with international standards (such as DOT/SAE in the United States, JWL/VIA in Japan, T Ü V in Europe, etc.), combining mass production stability and customization flexibility to meet differentiated needs, making them the preferred process solution for contemporary wheel hub manufacturing.

-

ANC Casting Spinning

ANC Casting SpinningThe casting spinning process is a combination of casting and spinning techniques, which achieves its forging grade strength (tensile strength ≥ 310MPa) by plastic deformation of the wheel rim. The rotary casting process breaks through the limitations of traditional casting and also has design freedom that cannot be compared to forging processes, making it an ideal choice for high-performance lightweight wheel hub manufacturing.

Tyotaku exclusively adopts the Japanese patented ANC casting process, combined with precision wheel spinning technology, which can achieve

1: The thinnest wall thickness of the wheel hub is 3mm (tolerance accuracy ± 0.3mm);

2: 18-22 inch wheel hub reduces weight by 1.2-1.8kg per piece;

3: Significantly improved material performance - with a tensile strength of over 310MPa (25% higher than traditional casting processes);

4: The product has passed SAE J328 standard certification and has exceeded one million fatigue cycles;

Tyotaku casted wheel hubs achieve 15% lightweighting while maintaining excellent impact resistance, making them particularly suitable for the lightweighting needs of new energy vehicles and meeting the demanding working conditions of high-performance sports cars and high load commercial vehicles.

-

Forge

ForgeAs a high-end aluminum alloy wheel manufacturer, Tyotaku possesses advanced hardware manufacturing equipment and leading software analysis technology, which are the core guarantees for producing high-performance aluminum wheels.

Based on years of experience serving globally renowned vehicle manufacturers and high-end after-sales brands, the Tyotaku technology R&D team has achieved scientific weight reduction of wheel hub structures through systematic data analysis and process optimization, while ensuring product quality.

Tyotaku forged aluminum wheels adopt industry-leading forging technology, combined with precision analysis technology and refined processing, to create top-level products that combine lightweight, high strength, and excellent aesthetic design.

Tyotaku high-performance forged aluminum wheels ensure safety and reliability in various harsh road conditions, while their ultimate lightweight characteristics significantly enhance vehicle handling and driving experience. The product adopts high-end design language, perfectly matching various car models, giving the whole vehicle a more dynamic and exquisite visual charm.